| Availability: | |

|---|---|

| Quantity: | |

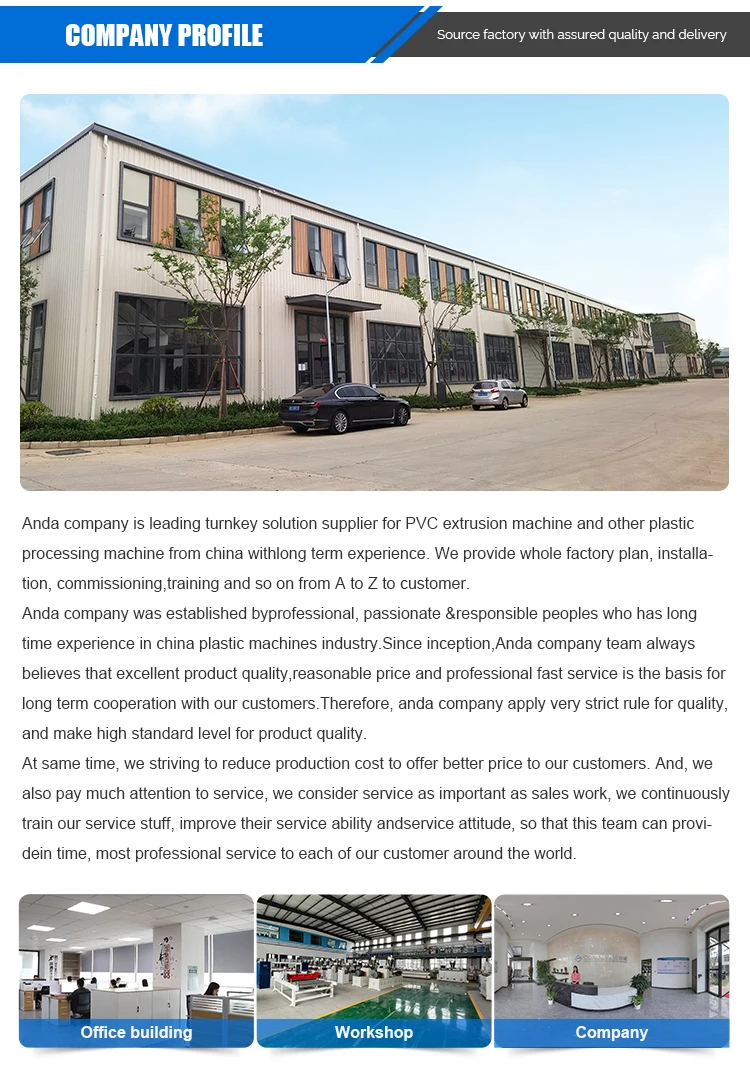

China

JINSE

PS fluted wall panel production line is used for making PS fluted wall panel which is now a popular product applied in decoration. It could help the decoration more exquisite and improve a level.

PS fluted wall panel making machine including for main parts, they are twin screw extruder, vacuum calibrator, hauling engine and cutting machine. Anda Machinery use world famous band of motor, engine, gearbox to produce and guarantee the quality of machine.

1. Twin Screw Extruder

Extruder adopts dedicated screw, make sure best plastisizing effect.

Extruder speed and haul off speed controlled by ABB frequency converter, saving power and easy adjusting speed.

Extruder temperature adopt PID control, temperature fluctuation self adjusting, it realize the high automatic level.

2. Vacuum Calibrator

Use vacuum system which could better achieve cooling accomplished results.

3. Hauling Machine

4. Cutting Machine

Use wear-resisting saw blade to imcrease the sharpness and the working life.

4. Final product display:

Main Features

1.High speed, double output than common production line, greatly decrease the labour cost and electricity cost and manage cost.

2.Extruder adopts dedicated screw, make sure best plastisizing effect

3.Extruder speed and haul off speed controlled by ABB frequency converter, saving power and easy adjusting speed

4.Extruder temperature adopt PID control, temperature fluctuation self adjusting, it realize the high automatic level

5.The caco3 filler can up to 300phr, formula cost is greatly reduced.

6.Equipped with infrared tracking device which can eliminate the problem of fluctuation of extrusion flow rate, further can make sure get best product

7.Lower power consumption,it can save 25-30% electrical power consumption comparing with most kind production line.

8.With online hot stamping, easy operation, saving labour.

Equipment parameters

model | PS65 | PS80 | PS90 | PS100 | PS120 | PS150 |

main extruder | SJ65 | SJ80 | SJ90 | SJ100 | SJ120 | SJ150 |

Vice extruder | SJ35 | SJ35 | SJ45 | SJ45 | SJ45 | SJ65 |

Main extruder power | 22Kw | 30Kw | 37Kw | 45Kw | 55Kw | 75Kw |

Average yield (estimated) | 30Kg/h | 50kg/g | 60kg/h | 70kg/h | 90kg/h | 120kg/h |

Host heating power | 14Kw | 18Kw | 22Kw | 26Kw | 30Kw | 40Kw |

Production speed | 0.5m/min-7m/min | |||||

Water tank | 6m | 8m | 10m | 10m | 12m | 14m |

tractor power | 2.2Kw | 3Kw | 3Kw | 4Kw | 5.5Kw | 7.5Kw |

Cutting Machine | cut from top to bottom | special | ||||

stacking rack | Length: 3m | |||||

Bronzing machine | 4 units | 6 units | 6 units | 8 units | 10 units | 12 units |

Embossing machine | 2 units | 2 units | 2 units | 2 units | 2 units | 2 units |

PS fluted wall panel production line is used for making PS fluted wall panel which is now a popular product applied in decoration. It could help the decoration more exquisite and improve a level.

PS fluted wall panel making machine including for main parts, they are twin screw extruder, vacuum calibrator, hauling engine and cutting machine. Anda Machinery use world famous band of motor, engine, gearbox to produce and guarantee the quality of machine.

1. Twin Screw Extruder

Extruder adopts dedicated screw, make sure best plastisizing effect.

Extruder speed and haul off speed controlled by ABB frequency converter, saving power and easy adjusting speed.

Extruder temperature adopt PID control, temperature fluctuation self adjusting, it realize the high automatic level.

2. Vacuum Calibrator

Use vacuum system which could better achieve cooling accomplished results.

3. Hauling Machine

4. Cutting Machine

Use wear-resisting saw blade to imcrease the sharpness and the working life.

4. Final product display:

Main Features

1.High speed, double output than common production line, greatly decrease the labour cost and electricity cost and manage cost.

2.Extruder adopts dedicated screw, make sure best plastisizing effect

3.Extruder speed and haul off speed controlled by ABB frequency converter, saving power and easy adjusting speed

4.Extruder temperature adopt PID control, temperature fluctuation self adjusting, it realize the high automatic level

5.The caco3 filler can up to 300phr, formula cost is greatly reduced.

6.Equipped with infrared tracking device which can eliminate the problem of fluctuation of extrusion flow rate, further can make sure get best product

7.Lower power consumption,it can save 25-30% electrical power consumption comparing with most kind production line.

8.With online hot stamping, easy operation, saving labour.

Equipment parameters

model | PS65 | PS80 | PS90 | PS100 | PS120 | PS150 |

main extruder | SJ65 | SJ80 | SJ90 | SJ100 | SJ120 | SJ150 |

Vice extruder | SJ35 | SJ35 | SJ45 | SJ45 | SJ45 | SJ65 |

Main extruder power | 22Kw | 30Kw | 37Kw | 45Kw | 55Kw | 75Kw |

Average yield (estimated) | 30Kg/h | 50kg/g | 60kg/h | 70kg/h | 90kg/h | 120kg/h |

Host heating power | 14Kw | 18Kw | 22Kw | 26Kw | 30Kw | 40Kw |

Production speed | 0.5m/min-7m/min | |||||

Water tank | 6m | 8m | 10m | 10m | 12m | 14m |

tractor power | 2.2Kw | 3Kw | 3Kw | 4Kw | 5.5Kw | 7.5Kw |

Cutting Machine | cut from top to bottom | special | ||||

stacking rack | Length: 3m | |||||

Bronzing machine | 4 units | 6 units | 6 units | 8 units | 10 units | 12 units |

Embossing machine | 2 units | 2 units | 2 units | 2 units | 2 units | 2 units |