| Availability: | |

|---|---|

| Quantity: | |

China

JINSE

Decoration PVC Marble Sheet Making Machine is applied to produce PVC sheet with width of 1220mm and length with 2440mm, thickness mostly from 2.5 to 4mm. The surface of PVC sheet generally treated by hot stamping or lamination, then coated by UV varnish. By switching film with different color. After coating UV glossy varnish, the surface of PVC sheet is more smooth and wearable. It can also produce LVT floor by some adjustment and with related auxiliary machines.

PVC sheet is widely used in hotel, office building, supermarket, KTV, massage club and other public areas.

Comparing with natural board and MDF sheet, PVC Marble sheet has the following advantages:

1. Cheap cost

2. Water-proof, insect prevention, moth proof

3. Easy and faster installation

4. Vivid color and glossy

5. Environment protection and no pollution

Main parameter of PVC marble sheet making machine:

| Item | Parameter | |

| Extruder | 80/156 | 92/188 |

| Thickness of Sheet | 2.8-3.5mm | 2-6mm |

| Size of Sheet | 1220*2440mm | 950*2440mm |

| Weight of Sheet | 17-25kg/piece | 12-36kg/piece |

| Output | 530 sheets/day (10T/24h) | 800 sheets/day (12-15T/24h) |

| Size of Machine | 25*2.5*3m | 28*2.5*3m |

| Suggested Workshop Size | 60*24*6m | 60*24*6m |

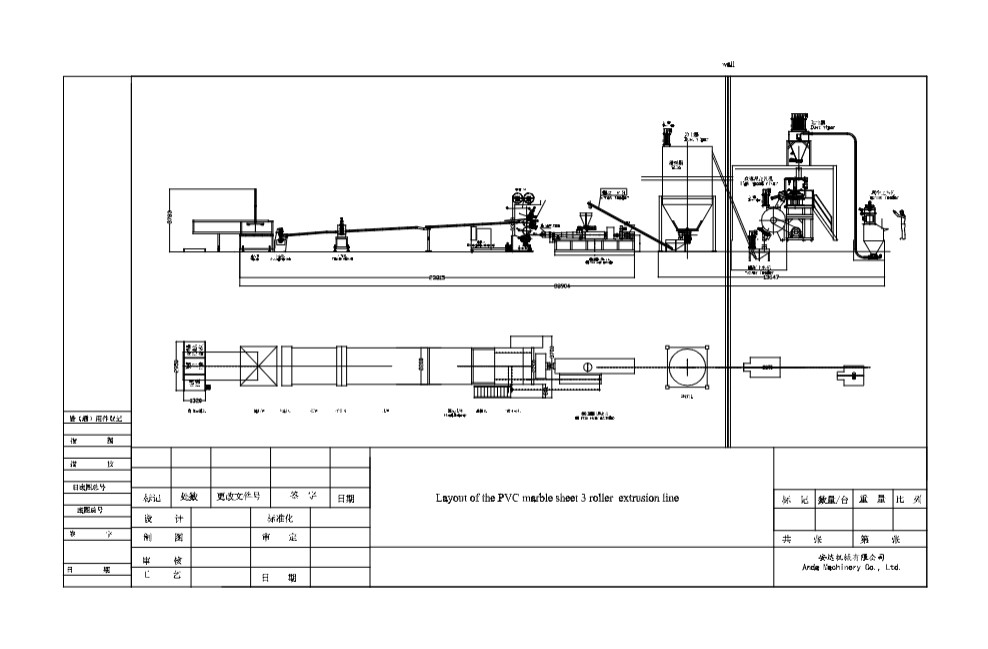

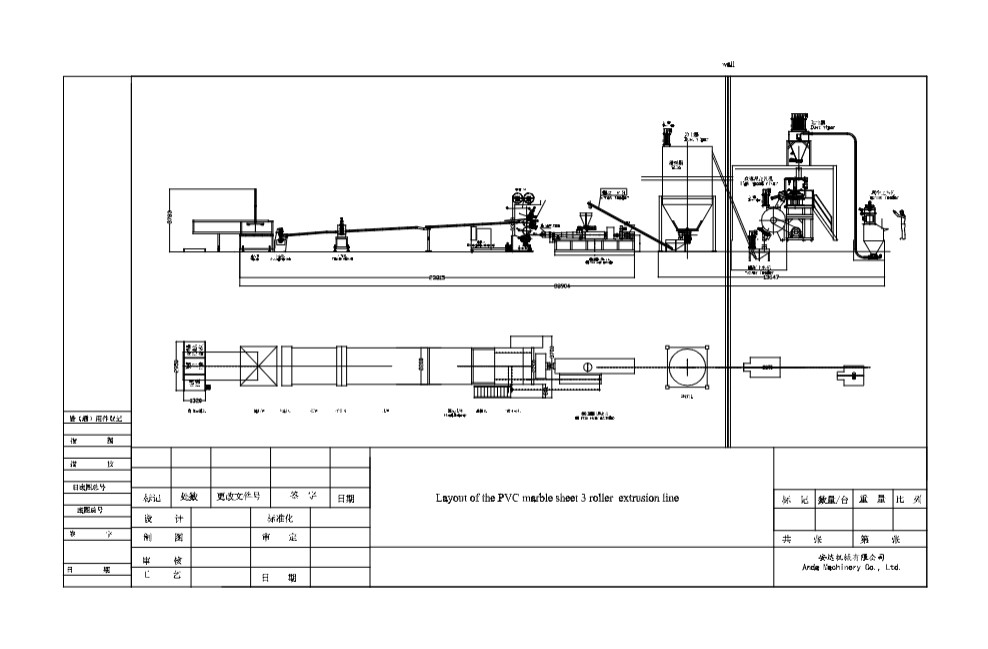

Whole factory layout of PVC marble sheet proudction line:

Company Profile:

Anda company was established by professional, passionate & responsible peoples who has long time experience in china plastic machines industry, Since inception, Anda company team always believes that excellent product quality reasonable price and professional fast service is the basis for long term cooperation with our customers, Therefore, anda company apply very strict rule for quality, and make high standard level for product quality. At same time, we striving to reducepro-duction cost to offer better price to our customers, And, we also pay much attention to service, we consider service as importantas sales work, we continuously train cur service stuff, improve their service ability and service attitude, so that this team can provide in time, most professional service to each of our customer around the world.

Decoration PVC Marble Sheet Making Machine is applied to produce PVC sheet with width of 1220mm and length with 2440mm, thickness mostly from 2.5 to 4mm. The surface of PVC sheet generally treated by hot stamping or lamination, then coated by UV varnish. By switching film with different color. After coating UV glossy varnish, the surface of PVC sheet is more smooth and wearable. It can also produce LVT floor by some adjustment and with related auxiliary machines.

PVC sheet is widely used in hotel, office building, supermarket, KTV, massage club and other public areas.

Comparing with natural board and MDF sheet, PVC Marble sheet has the following advantages:

1. Cheap cost

2. Water-proof, insect prevention, moth proof

3. Easy and faster installation

4. Vivid color and glossy

5. Environment protection and no pollution

Main parameter of PVC marble sheet making machine:

| Item | Parameter | |

| Extruder | 80/156 | 92/188 |

| Thickness of Sheet | 2.8-3.5mm | 2-6mm |

| Size of Sheet | 1220*2440mm | 950*2440mm |

| Weight of Sheet | 17-25kg/piece | 12-36kg/piece |

| Output | 530 sheets/day (10T/24h) | 800 sheets/day (12-15T/24h) |

| Size of Machine | 25*2.5*3m | 28*2.5*3m |

| Suggested Workshop Size | 60*24*6m | 60*24*6m |

Whole factory layout of PVC marble sheet proudction line:

Company Profile:

Anda company was established by professional, passionate & responsible peoples who has long time experience in china plastic machines industry, Since inception, Anda company team always believes that excellent product quality reasonable price and professional fast service is the basis for long term cooperation with our customers, Therefore, anda company apply very strict rule for quality, and make high standard level for product quality. At same time, we striving to reducepro-duction cost to offer better price to our customers, And, we also pay much attention to service, we consider service as importantas sales work, we continuously train cur service stuff, improve their service ability and service attitude, so that this team can provide in time, most professional service to each of our customer around the world.