| Availability: | |

|---|---|

| Quantity: | |

China

JINSE

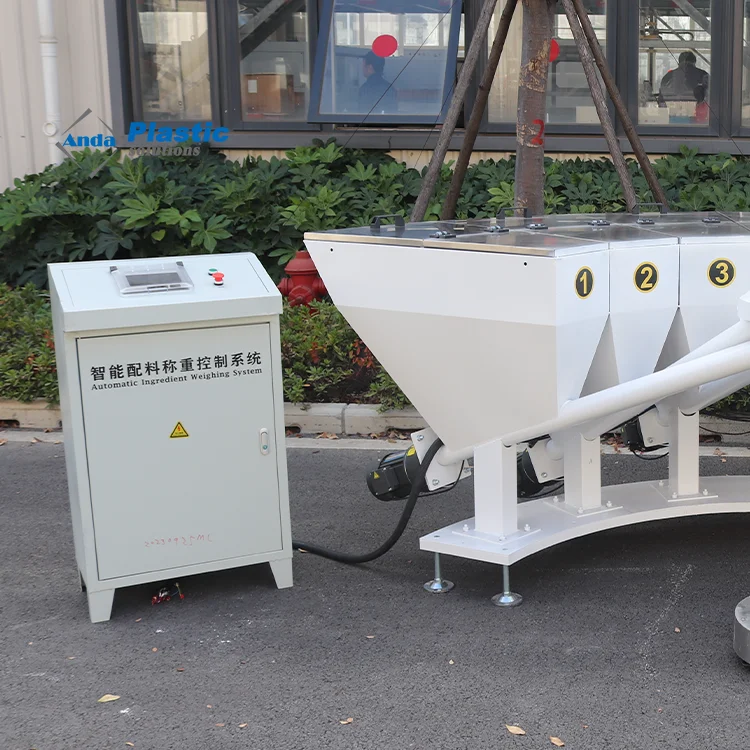

1. Accuracy: 10 grams;

2. Ingredients time: 100 seconds/20 kg;

3. Conveying method: spiral feeding;

4. Conveying motor power: 1.5KW;

5. Conveying method: frequency conversion;

6. Pneumatic pusher: One set is standard (anti-bridging function)

7. The whole machine is welded with stainless steel to complete the quantitative proportioning of auxiliary materials.

To weigh the additives is an repeated and tedious job, the workers may make weighing mistake easily, which will influence the final product's quality. so we developed this PVC additives auto-weighing machine to instead of traditional manual weighing. It could weigh the additives automatically, such as stearic acid, wax, titanium dioxide, whitener, carbon black etc. This system could avoid the mistake of manual weighing and also keep the workshop clean.

* Easy to operate: Try to use graphics and symbols to describe the operation process to make the operation interface more friendly and intuitive.

* Complete functions: This system does not need to modify the program. It can adapt to different requirements only by setting the operation panel and selecting some parameters. This machine can store multiple recipes and switch at will.

Product Details

Our headquarter located Zhangjiagang city with convenient transportation access from shanghai and our factory are located at WUXI city, and the location is only five minutes away from WUXI east high speed strain station and 10 minutes away from WUXI airport with easy access from shanghai and Beijing and Guangzhou. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment including Various CNC machine. In addition, we have obtained certificates. ISO9001 Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as Turkey, USA, uzbekistan, Pakistan, Indonesia .

| |

Why choose us? | |

Anda is specialized for the products with long time experience. We always pay attention to the quality of equipment we manufactured, and we have sufficient technical team which can go to customer factory in very short time when it’s required. And so far we have installed machines at most hot spot region around the world, the stable running of machines are the best explanation. Welcome contact us to know reference customer near to your region. | |

How long the machine can be delivered? | |

Generally we have the semi-ready machines or even ready machine at store, so the delivery time is very fast, normally around 30-40days, depending on the kind of machines and the quantity of machines you will order | |

What kind payment terms? | |

We can accept multiple kind payment terms, like T/T, LC,D/P(advance payment required) etc. | |

How to install the machines? | |

Upon customer’s requirement, we can send technician to customer’s factory for installation and training. Meantime, we can also send experience Chinese master to work at customer factory for 3month to one year or even longer time. So the Chinese technician will install machines, teach local workers about machine installation and operations and so on. | |

What’s the Warranty? | |

One year since installation completed. In the warranty period, in case any parts broken by uncontrolled factor, we will be responsible and send the parts immediately by courier or air cargo. | |

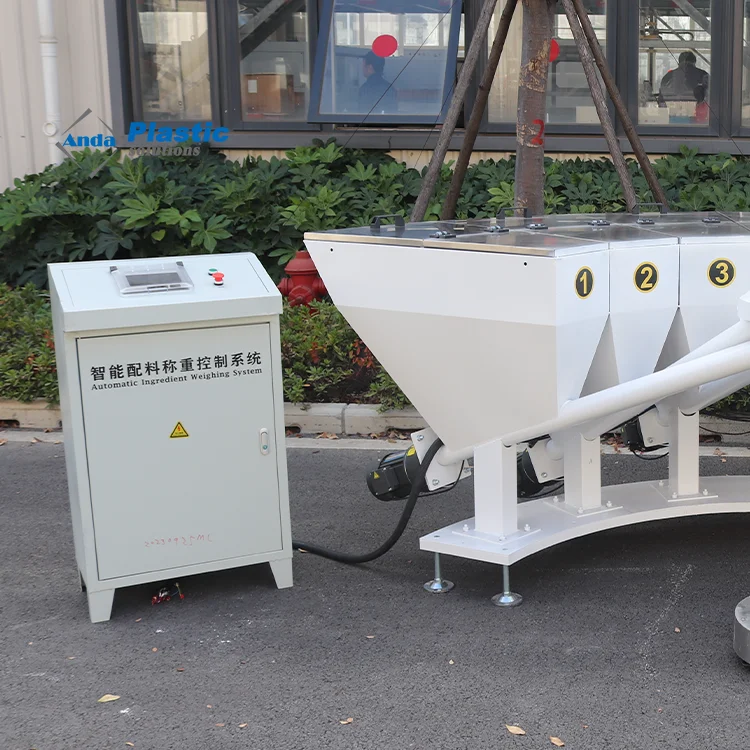

1. Accuracy: 10 grams;

2. Ingredients time: 100 seconds/20 kg;

3. Conveying method: spiral feeding;

4. Conveying motor power: 1.5KW;

5. Conveying method: frequency conversion;

6. Pneumatic pusher: One set is standard (anti-bridging function)

7. The whole machine is welded with stainless steel to complete the quantitative proportioning of auxiliary materials.

To weigh the additives is an repeated and tedious job, the workers may make weighing mistake easily, which will influence the final product's quality. so we developed this PVC additives auto-weighing machine to instead of traditional manual weighing. It could weigh the additives automatically, such as stearic acid, wax, titanium dioxide, whitener, carbon black etc. This system could avoid the mistake of manual weighing and also keep the workshop clean.

* Easy to operate: Try to use graphics and symbols to describe the operation process to make the operation interface more friendly and intuitive.

* Complete functions: This system does not need to modify the program. It can adapt to different requirements only by setting the operation panel and selecting some parameters. This machine can store multiple recipes and switch at will.

Product Details

Our headquarter located Zhangjiagang city with convenient transportation access from shanghai and our factory are located at WUXI city, and the location is only five minutes away from WUXI east high speed strain station and 10 minutes away from WUXI airport with easy access from shanghai and Beijing and Guangzhou. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment including Various CNC machine. In addition, we have obtained certificates. ISO9001 Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as Turkey, USA, uzbekistan, Pakistan, Indonesia .

| |

Why choose us? | |

Anda is specialized for the products with long time experience. We always pay attention to the quality of equipment we manufactured, and we have sufficient technical team which can go to customer factory in very short time when it’s required. And so far we have installed machines at most hot spot region around the world, the stable running of machines are the best explanation. Welcome contact us to know reference customer near to your region. | |

How long the machine can be delivered? | |

Generally we have the semi-ready machines or even ready machine at store, so the delivery time is very fast, normally around 30-40days, depending on the kind of machines and the quantity of machines you will order | |

What kind payment terms? | |

We can accept multiple kind payment terms, like T/T, LC,D/P(advance payment required) etc. | |

How to install the machines? | |

Upon customer’s requirement, we can send technician to customer’s factory for installation and training. Meantime, we can also send experience Chinese master to work at customer factory for 3month to one year or even longer time. So the Chinese technician will install machines, teach local workers about machine installation and operations and so on. | |

What’s the Warranty? | |

One year since installation completed. In the warranty period, in case any parts broken by uncontrolled factor, we will be responsible and send the parts immediately by courier or air cargo. | |