| Availability: | |

|---|---|

| Quantity: | |

China

JINSE

WPC Door Frame Making Machine Production LIne is used to produce various kind WPC profiles, such as WPC skirting board, WPC door profile, WPC corner bead, WPC folding door profile, WPC moldings and so on. the surface of WPC skirting board can be treated by printing, lamination, which can make marble, wooden design on surface of product to match with WPC floor .

Features of WPC Door Frame Making Machine Production LIne

1.speed controlled by inverter, saving power and easy to adjust speed.

2.extruder temperature controlled by Omron intelligent controller, the temperature can be adjusted 3.automatically.low power consumption: minimum total production line consumption is 25kw/hour, economical price, it's suitable for large scale investment.

Model:

Model | 51/105 | 55/110 | 65/132 |

Extruder | SJSZ51/105 | SJSZ55/110 | SJSZ65/132 |

capacity per 24h | 2200kg | 3000-3500kg | 3000-3500kg |

Motor power | 15kw | 22kw | 37kw |

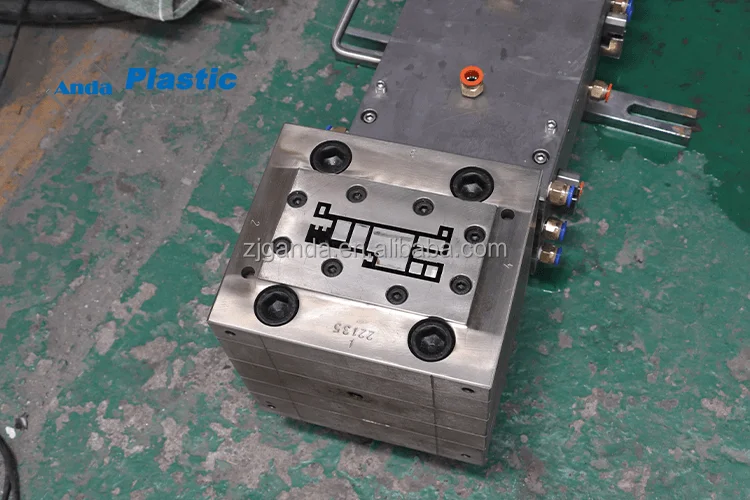

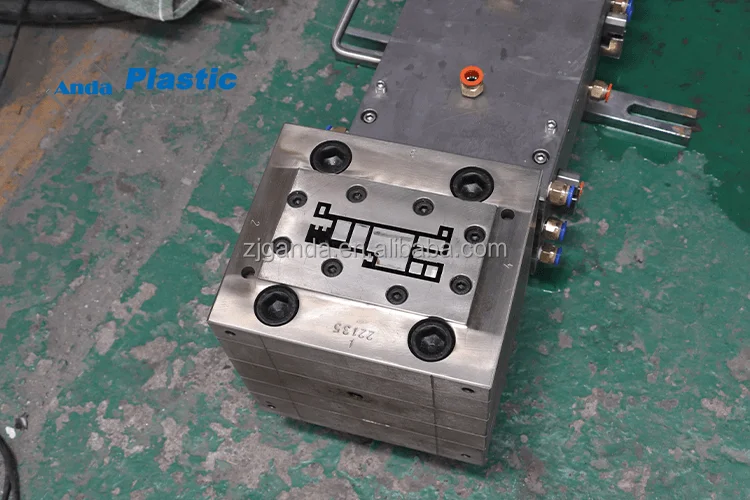

1. WPC Door Frame Making Machine Production Line——Extruder

Extruder adopts WPC Door Frame dedicated screw, make sure best plastisizing effect

Extruder speed and haul off speed controlled by ABB frequency converter, saving power and easy adjusting speed

Extruder temperature adopt PID control, temperature fluctuation self adjusting, it realize the high automatic level

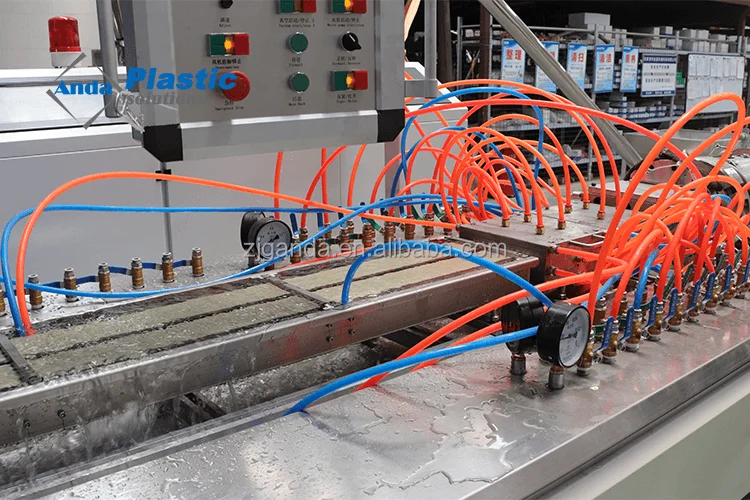

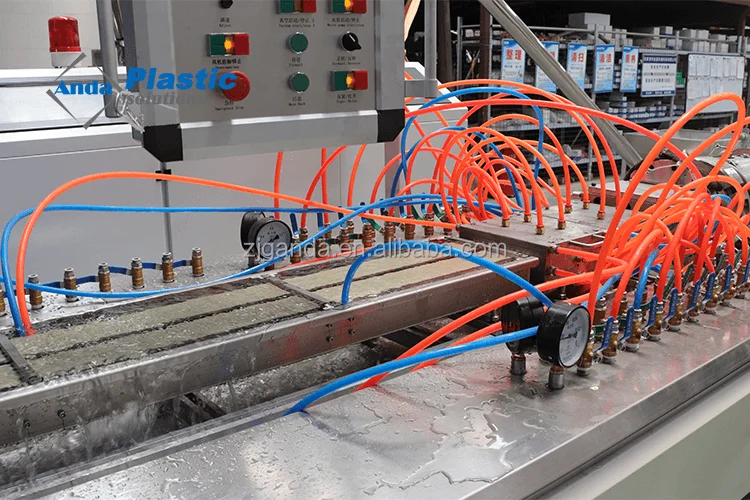

2. WPC Door Frame Making Machine Production LIne——Cooling Table

Use vacuum system which could better achieve cooling accomplished results.

3. WPC Door Frame Making Machine Production LIne——Hauling Machine & Cutting Machine

Hauling Machine adopt alloy rubber blocks, strictly keep the smooth transition of profile.

Cutting Machine adopt stainless steel material which is wear-resistant and durable. It also equipped with dust cleaner device.

4. WPC Door Frame Making Machine Production LIne——Stacker

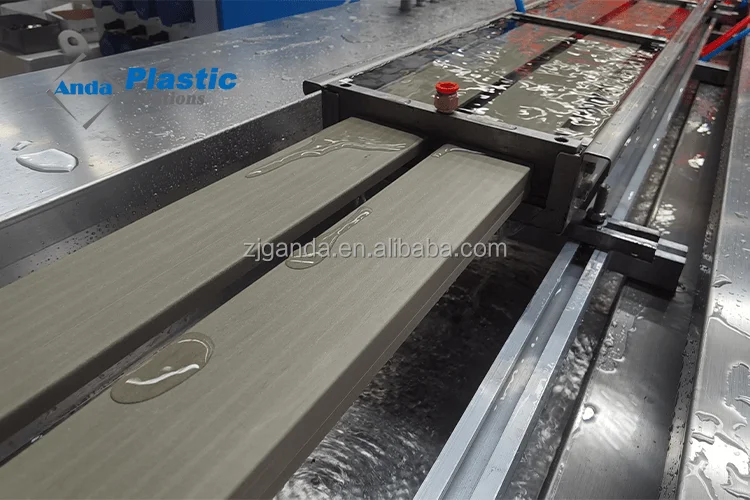

5. WPC Door Frame Making Machine Production LIne---Final products

\

Our headquarter located Zhangjiagang city with convenient transportation access from shanghai and our factory are located at WUXI city, and the location is only five minutes away from WUXI east high speed strain station and 10 minutes away from WUXI airport with easy access from shanghai and Beijing and Guangzhou. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment including Various CNC machine. In addition, we have obtained certificates. ISO9001 Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as Turkey, USA, uzbekistan, Pakistan, Indonesia .

WPC Door Frame Making Machine Production LIne is used to produce various kind WPC profiles, such as WPC skirting board, WPC door profile, WPC corner bead, WPC folding door profile, WPC moldings and so on. the surface of WPC skirting board can be treated by printing, lamination, which can make marble, wooden design on surface of product to match with WPC floor .

Features of WPC Door Frame Making Machine Production LIne

1.speed controlled by inverter, saving power and easy to adjust speed.

2.extruder temperature controlled by Omron intelligent controller, the temperature can be adjusted 3.automatically.low power consumption: minimum total production line consumption is 25kw/hour, economical price, it's suitable for large scale investment.

Model:

Model | 51/105 | 55/110 | 65/132 |

Extruder | SJSZ51/105 | SJSZ55/110 | SJSZ65/132 |

capacity per 24h | 2200kg | 3000-3500kg | 3000-3500kg |

Motor power | 15kw | 22kw | 37kw |

1. WPC Door Frame Making Machine Production Line——Extruder

Extruder adopts WPC Door Frame dedicated screw, make sure best plastisizing effect

Extruder speed and haul off speed controlled by ABB frequency converter, saving power and easy adjusting speed

Extruder temperature adopt PID control, temperature fluctuation self adjusting, it realize the high automatic level

2. WPC Door Frame Making Machine Production LIne——Cooling Table

Use vacuum system which could better achieve cooling accomplished results.

3. WPC Door Frame Making Machine Production LIne——Hauling Machine & Cutting Machine

Hauling Machine adopt alloy rubber blocks, strictly keep the smooth transition of profile.

Cutting Machine adopt stainless steel material which is wear-resistant and durable. It also equipped with dust cleaner device.

4. WPC Door Frame Making Machine Production LIne——Stacker

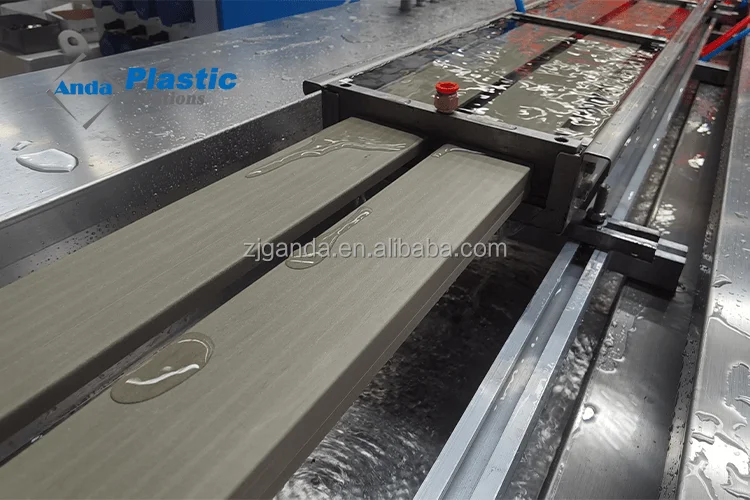

5. WPC Door Frame Making Machine Production LIne---Final products

\

Our headquarter located Zhangjiagang city with convenient transportation access from shanghai and our factory are located at WUXI city, and the location is only five minutes away from WUXI east high speed strain station and 10 minutes away from WUXI airport with easy access from shanghai and Beijing and Guangzhou. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment including Various CNC machine. In addition, we have obtained certificates. ISO9001 Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as Turkey, USA, uzbekistan, Pakistan, Indonesia .